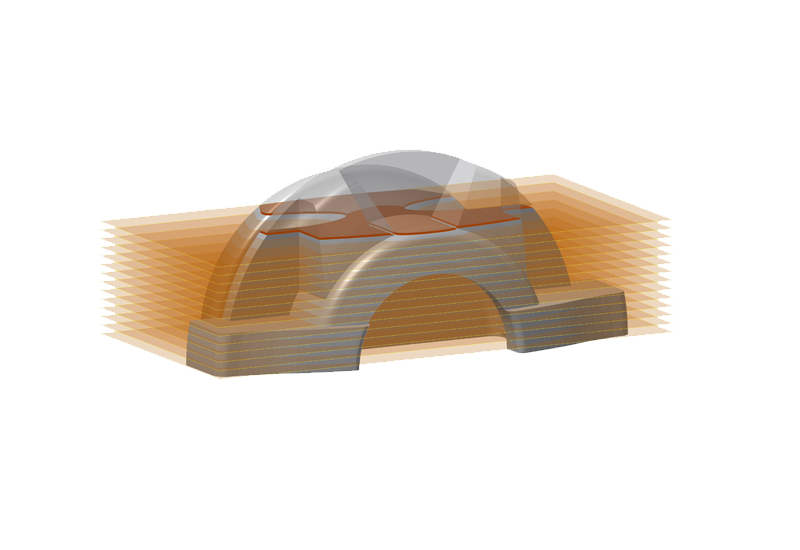

MIMplus Technologies provides the production of complex-shaped metal parts using various 3D-printing technologies. The 3D-printing process is similar to metal powder injection moulding process. The “green parts”, which are produced in first step, are further converted into purely metallic components during the subsequent de-binding and sintering processes. The selected 3D-printing processes are particularly suitable for the low-volume production of prototypes in case when the usage of the MIM process is not economically feasible.

Mechanical properties and the microstructure of the 3D-printed components are comparable to those of MIM components. Unlike melting processes, the components acquired by sintering have a homogeneous microstructure and free from residual stresses. Typically, densities of > 96% are achieved.

The 3D-printed and sintered components meet the highest requirements for surface quality but can also be further processed by standard post-processing processes. Currently available materials are the stainless steel 316L and the titanium alloy Ti6Al4V. Other materials are currently being developed.