Assembly

Assembly

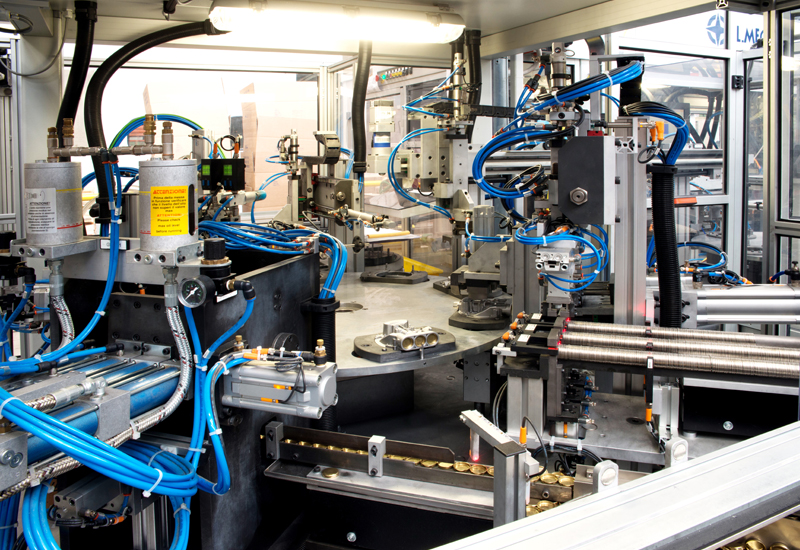

We already support our customers in the development phase, to ensure that the advantages of the respective process (MIM / AM) can be fully utilised for the subsequent assembly of a component. The support service also includes the determination of an optimal joining process and the degree of automation. Depending on the quantity and complexity of an assembly, it can be fully automatic, semi-automatic or manual.

Connection technologies

Connection technologies

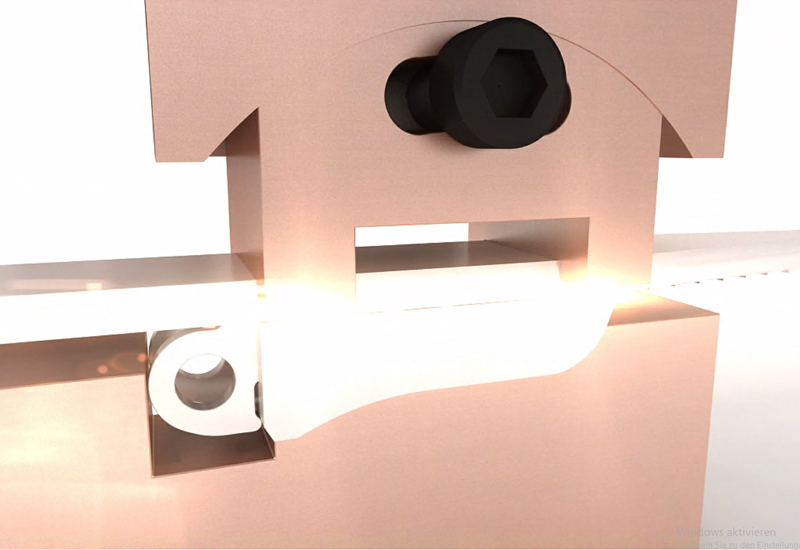

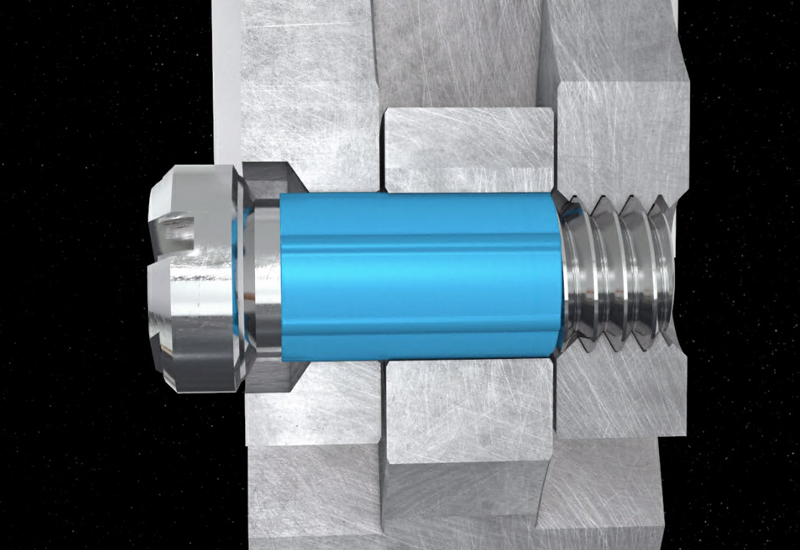

In addition to screwed and riveted connections, we also offer resistance and laser welding as well as soldering and adhesive connections. In addition to these conventional methods, our processes (MIM / AM) offer further possibilities such as green part joining or co-sintering. In this process, either two green parts or one green compact is inseparably joined to a metal component.

Laser processing

Laser processing

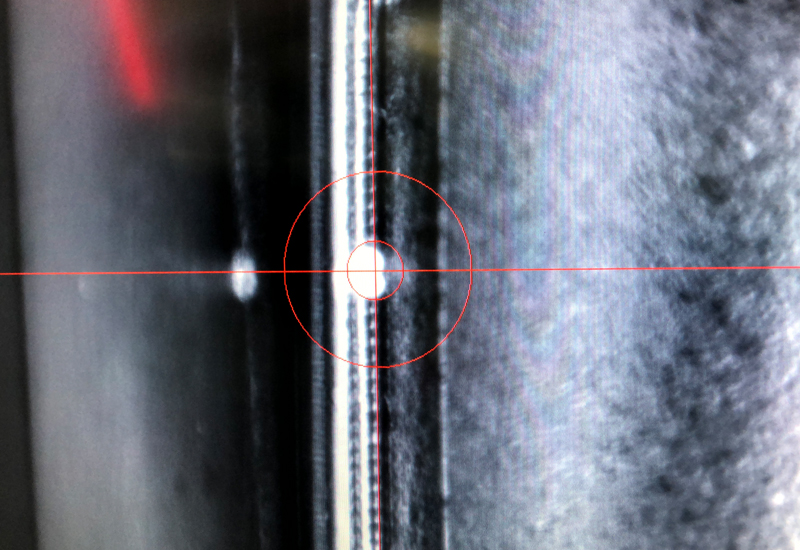

We apply different laser machining processes. Processing of “green parts” by means of lasers, for example laser drilling, offers significant advantages in terms of burr formation, process times and tool wear. We have a substantial know-how particularly in laser welding of small, thin-walled sintered parts. Laser labeling and laser texturing of finished components is part of our range of services.

Welding and soldering

Welding and soldering

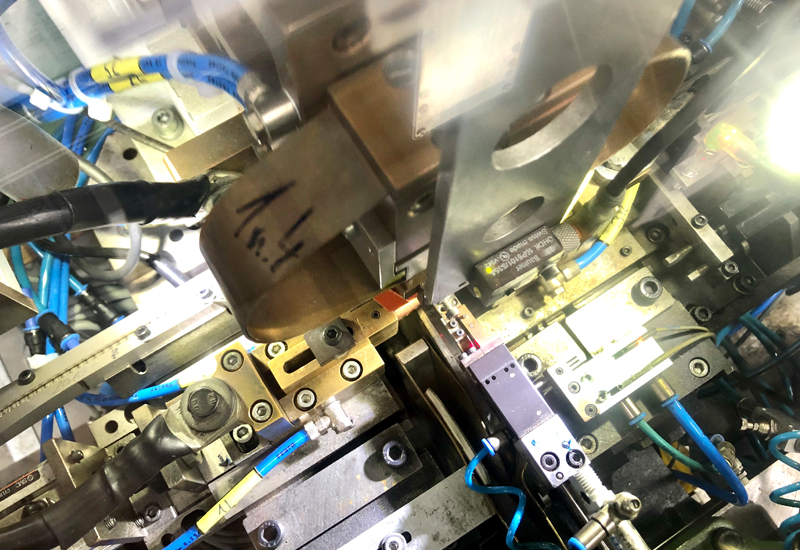

We are specialists in the automation of welding and soldering processes.

Our electrical department, construction, automation technology have put many years of experience in the construction of semi-automated and full-automated special machines such as assembly machines.

Adhesive bonding

Adhesive bonding

Adhesive bonding has become the preferred joining technology for many applications. We provide you expert advice in selecting the adhesive according to your demands. Furthermore, we offer our customers suitable cleaning procedures for adhesive surfaces and the relevant equipment for mixing, dosing and applying the adhesives properly.

Plastic overmolding

Plastic overmolding

Plastic overmolded MIM parts are used in many industries. MIMplus has many years of experience in the overmolding of safety screws and metal parts for customers in a wide range of industries. If a higher temperature resistance is required Peek can also be used in addition to Akulon.