Machining

Machining

In order to be able to offer ready-to-install solutions and assemblies, in addition to MIM and AM processes, we are also proficient in all common machining processes.

In particular, the machining of small, high-precision components is one of our strengths. MIM and AM processes often involve the calibration of components, which is more cost-effective than machining. Our machinery is flexibly equipped in order to be able to select the optimum degree of automation for each component for the requested number of pieces.

Surface treatment

Surface treatment

MIMplus is one of the leading manufacturers of refined surfaces. We have a wide spectrum of production technologies which have been applied in stainless steel and titanium components over the years: vibratory grinding, sandblasting and polishing. We are experts in surface treatment and provide the sufficiently trained staff in project management, production, quality assurance and final check.

Vibratory grinding

Vibratory grinding

Using the process of vibratory grinding we ensure the cost-effective removal of residual burrs and set the desired finish roughness. Moreover, it can be used to prepare component surface for further processing, for example polishing. Possessing a variety of equipment, more than 25 pieces, with different technologies we can always offer you the optimal process for your component.

Electroplating

Electroplating

Depending on customer’s requirements, we can provide parts with functional or refined surfaces in our fully automated electroplating shop. Above all, we offer surface passivation and bluing of steel components.

Smaller quantities of the components can be economically machined at our manual electroplating line.

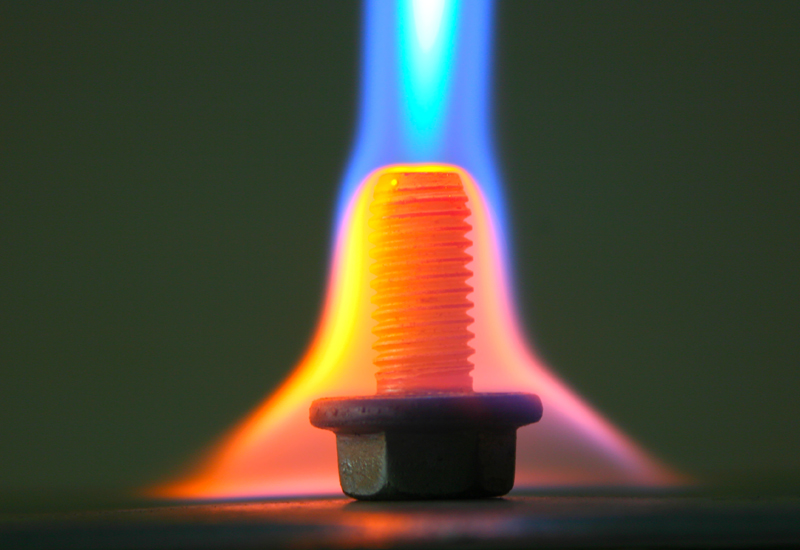

Heat treatment

Heat treatment

Together with selected industrial partners, we offer heat treatment for hardening, application hardening, surface hardening, vacuum hardening, nitrating, nitrocarburizing, plasma nitrating and annealing. Some selected heat treatments can also be carried out in-house.

Hot isostatic pressing (HIP)

Hot isostatic pressing (HIP)

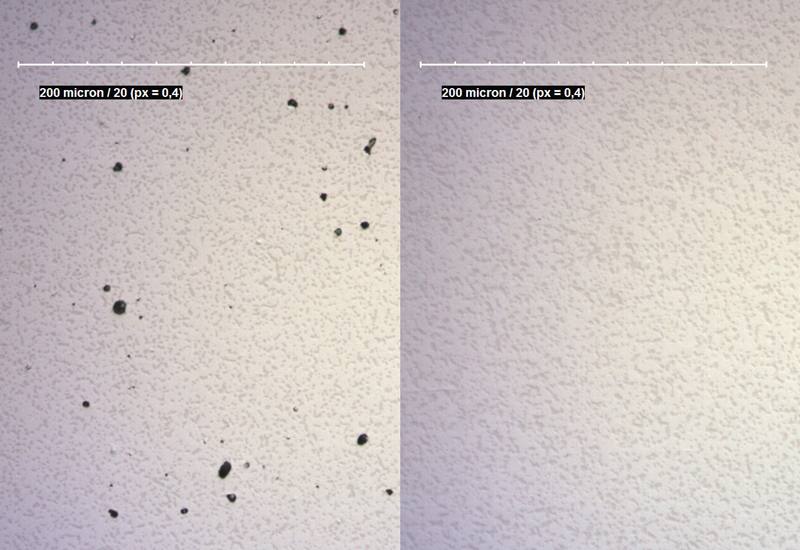

After sintering, MIM and AM parts have almost the same density as conventionally produced parts. Typical densities are > 97% of the rolled material.

If higher densities and a pore-free microstructure are required, the respective parts can be reworked with the help of hot isostatic pressing (HIP). MIMplus offers HIP in cooperation with qualified partners.